We are passionate about our product: We enable the production of green steel by recycling catalysts. We transform metal containing waste streams into a first class FeMoNi alloy, so (stainless)steel manufacturers can save on natural resources and lower their CO₂-footprint. Read all about it.

We are passionate about our product: We enable the production of green steel by recycling catalysts. We transform metal containing waste streams into a first class FeMoNi alloy, so (stainless)steel manufacturers can save on natural resources and lower their CO₂-footprint. Read all about it.

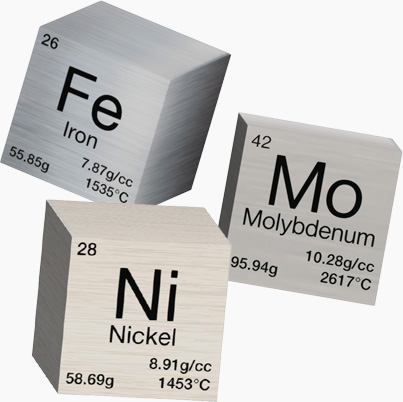

What’s FeMoNi?

FeMoNi is an alloy from a fully recycled background. Our alloy contains Iron (Fe), Molybdenum (Mo) and Nickel (Ni) which makes it an ideal additive for producers of Stainless-steel grades like 316, 316L, 321 and 329 (Duplex and Super Duplex). The waste materials we recycle to create our FeMoNi alloy come from the (petro) chemical industry and surface treatment industries. Our alloy is fully REACH registrated for our customers on the European market.

Compare it to virgin

Ecochain performed a Life Cycle Assessment in accordance with the ISO14040 and 14044 standards for our FeMoNi alloy, comparing it to virgin material like FeMo and FeNi. These are the take-aways:

Turning scrap into steel

Firstly, waste materials are collected from the disposers of spent catalyst and metal containing residues. Most of the spent catalysts that we collect are coming from oil refineries or chemical plants. After being collected, we recycle these spent materials via thermal treatment by calcining (Phosphor and Sulphur removal) and melting it afterward to an alloy. The metals Molybdenum and Nickel are being recovered in this process. These are also important ingredients for stainless steel.

We recycle these metals into a variety of high-quality and sustainable alloys. We offer these ‘new’ secondary materials which contain a combination of elements Fe, Mo and Ni directly to end user (Stainless-steel producers), who are using them to replace materials from mining and consume less energy in their production process by using our combination alloy.

Our vision: no more waste

Generally, these used materials are seen as waste, but at Moxba, we see the potential of these used materials to convert them to first class alloys. Our goal is to recycle as much metal waste as possible into usable material. With 50 years of experience in this business, we know how to do that. And this way, we make sure you can create more sustainable products.