With 50 years of experience in recycling Grindings, Powder and Dust bearing waste streams, we are your reliable partner.

With 50 years of experience in recycling Grindings, Powder and Dust bearing waste streams, we are your reliable partner.

We specialize in the recycling of Molybdenum and/or Nickel grindings, powders, dusts and sweeps. Both in metallic and oxide form. Our focus is on Molybdenum and Nickel, but we are also open to materials containing Vanadium, Tungsten, Cobalt, Copper, and Zinc.

Whatever the shape or form, if it contains valuable metals, we can process it sustainably and responsibly.

We are experts in recycling Molybdenum and Nickel waste streams generated from:

Thermal and plasma spraying

Plasma welding

Metal casting and forging

Stainless steel production (304/316)

Electroplating and surface treatment industries

We provide Full-loop recycling with our state of the art processes and technologies and the use of renewable energy (hydropower), enable us to recover metals from waste streams and spent catalysts with an unrivalled low carbon footprint: 85% lower CO2-emission, compared to conventional mined metals.

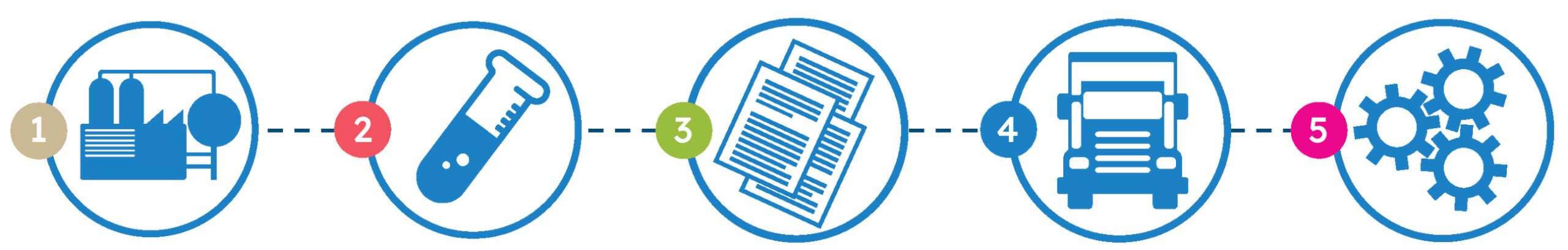

E.g.: Oil refineries, chemical plants

Arrangements for documents and licenses for each procedure

Thermal treatment and melting processes

Sampling and analytical services

Supporting transportation in a safe and responsible way

E.g.: Oil refineries, chemical plants

Sampling and analytical services

Arrangements for documents and licenses for each procedure

Supporting transportation in a safe and responsible way

Roasting, Thermal treatment and melting processes

Firstly, waste materials are collected from the disposers of spent catalyst and metal containing waste streams. Most of the spent catalysts that we collect are coming from oil refineries or chemical plants. After being collected, we recycle these spent materials via thermal treatment by calcining (Phosphor and Sulphur removal) and melting it afterward to an alloy. The metals Molybdenum and Nickel are being recovered in this process. These are also important ingredients for stainless steel.

We recycle these metals into a variety of high-quality and sustainable alloys. We offer these ‘new’ secondary materials which contain a combination of elements Fe, Mo and Ni directly to end user (Stainless-steel producers), who are using them to replace materials from mining and consume less energy in their production process by using our combination alloy.

Because we recycle in the most sustainable way possible, leading to the lowest carbon footprint in the industry. Sustainability is our keyword, not only in recycling, but also in our partnerships. We take care of everything for you. From logistics to compliance and recycling. Let us handle it.

Generally, these used materials are seen as waste, but at Moxba, we see the potential of these used materials to convert them to first class alloys. Our goal is to recycle as much metal waste as possible into usable material. With 50 years of experience in this business, we know how to do that. And this way, we make sure there is more green steel produced.

We are your reliable partner in sustainable metal recycling!